At ASI, we value Quality as the main driver to maintain our competitive advantage.

Our commitment to Quality is crucial to:- Retain existing customers and acquire new ones

- Maximize value to customers by providing optimum product performance at minimum cost

- Maintain our reputation as the preeminent global creator and supplier of drive systems for specialized electric machines

Our employees are empowered to focus on meeting or exceeding the expectations set forth by our customers and emerging markets.

Quality Policy

The quality of our products and services is very important to our customers; therefore quality is the foundation of our corporate culture and is every associate’s responsibility.

Our objective is to continually improve our products, processes and on-time performance, while maximizing productivity in order to provide products and service that meet customer requirements.

Quality Assurance

ASI believes that Quality must be caused, not controlled. It is the fabric of our organization. We believe that Quality comes from our commitment to be process oriented. Our primary focus is to ensure that our inputs are in control and to implement continuous improvement efforts at every opportunity.

We continually rely on Six-Sigma and Quality tools to achieve our goals, including, but not limited to:- ISO 9001:2015

- Real Time Statistical Process Control

- Strategic Root Cause Analysis

- Failure Mode and Effect Analysis

- ANOVA Gauge R&R (ANalysis Of VAriance Gauge Repeatability & Reproducibility)

- Process Capabilities

- Strategic Supplier Quality Management

Quality Measurement

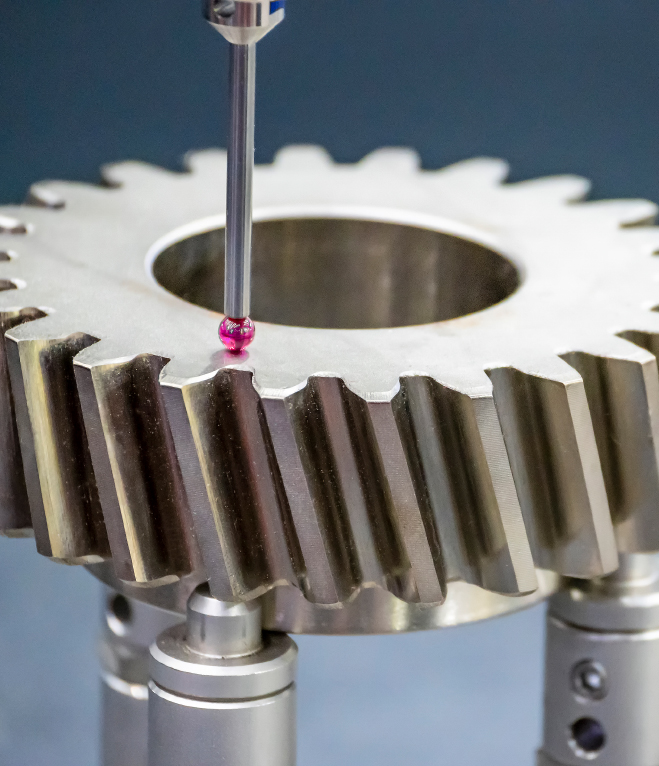

ASI invests heavily in state-of-the art precision measuring equipment to ensure that our components are produced accurately. Our QC lab is fully equipped to measure every aspect of all electromechanical components, whether manufactured in-house or purchased. Every finished product undergoes a rigorous computerized end-of-line testing process with network capabilities so that we can monitor performance, variation and drift.

Some of our fully calibrated QC equipment includes:- Fully automated CMM (Coordinate Measuring Machine)

- CNC automated Gear Inspection Machine

- Dynamometers

- Optical Comparator

- Hardness Testers

- Oscilloscopes

- Vibration and Noise Decibel Meters

- Programmable LCR Tester

- Electronic Torque Meters

- Programmable Pressure Testers

- Electronic Microscope

- Stroboscopes

- Hand precision measuring tools: calipers, micrometers, indicators, height gauges, depth gauges, etc.

- Complete standards/references: Jo-blocks, go/no-go gauges, diameter pins, feeler gauges, surface roughness, etc.

ASI Drives maintains our DEKRA certified QMS to the ISO 9001:2015 standard.

Get In Touch

Contact us to learn more or sign up for our newsletter.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.